Just How to Prevent Weld Undercut: Necessary Tips for Welders

Just How to Prevent Weld Undercut: Necessary Tips for Welders

Blog Article

A Comprehensive Overview to Identifying, Preventing, and Fixing Undercut Welding Problems in Your Welding Jobs

In the world of welding, coming across undercut issues is an usual challenge that can endanger the architectural stability and general quality of your welding projects. Keep tuned as we check out the necessary components of determining, avoiding, and fixing undercut welding troubles, providing you with beneficial insights and strategies to elevate your welding abilities to the following degree.

Usual Reasons of Undercut Welding

Undercut welding, an usual concern in welding procedures, can be triggered by different aspects that require to be very carefully recognized and addressed to ensure the integrity of the weld joint. Among the main sources of undercut welding is excessive warm input. When the welding specifications, such as voltage, present, or travel speed, are not correctly set, an extreme quantity of warm can be created. This excess warmth leads to the melting and subsequent removal of the base material along the sides of the weld joint, producing a groove called undercut.

Another usual cause of undercut welding is improper welding strategy. Determining these origin causes and executing corrective actions is important in stopping and fixing undercut welding issues in welding projects.

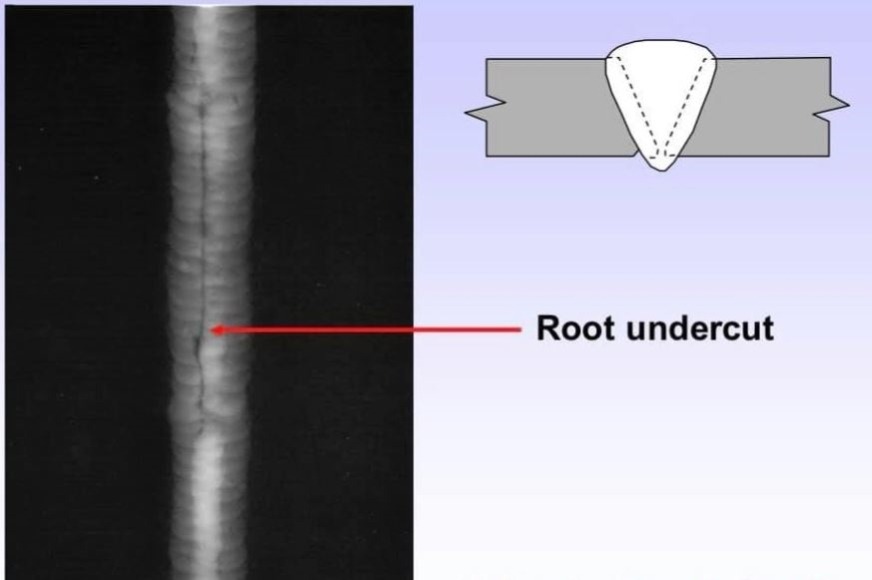

Identifying Undercut in Welds

To determine undercut properly, correct lighting and zoom tools are important to evaluate the weld joint thoroughly. Utilizing tools such as a welding gauge or a magnifying glass can assist in spotting even the smallest undercut imperfections. In addition, running a finger or a fingernail along the weld joint can sometimes disclose undercut, as the surface might really feel uneven or have a dip where the undercut exists.

Safety Nets for Undercut

Having a deep understanding of the reasons of undercut in welds allows for the execution of efficient precautionary actions to keep weld high quality and integrity. These settings must be optimized to protect against excessive heat input, which can lead to damage formation.

Strategies for Repairing Undercut

Raising the welding existing or minimizing the travel speed can aid fill in the undercut. Additionally, transforming the welding technique from a push to a drag or vice versa can additionally assist reduce undercut.

An additional technique is to utilize a weaving activity while welding to make sure proper sidewall combination and fill in the undercut. By oscillating the welding arc back and forth within the weld joint, the welder can deposit much more filler material into the undercut areas, properly eliminating the defect.

Moreover, grinding out the undercut and rewelding the joint can be a viable option for a lot more serious undercut problems - Preventing weld undercut. This procedure entails removing the undercut section, preparing the base steel, and after that rewelding the joint with proper welding parameters and methods to stop undercut from reoccurring

Professional Tips for Staying Clear Of Undercut

Utilizing appropriate welding strategies and maintaining control over crucial welding parameters are vital strategies for welders aiming to avoid undercut in their weld joints. In addition, selecting the suitable welding procedure and filler steel for the particular application can aid avoid undercut. Preserving a constant traveling rate throughout the welding process is another vital pointer to protect against undercut.

Verdict

Finally, determining, stopping, and dealing with undercut welding problems in your welding projects is vital for ensuring strong and resilient welds. Preventing weld undercut. By understanding the common root causes of undercut, being able to identify it in welds, executing safety nets, and making use of correct strategies for dealing with undercut, you can prevent prospective problems web link and create premium welds. Complying with specialist pointers for staying clear of undercut can aid you enhance your welding skills and produce far better lead to your projects

Undercut welding, a common concern in review welding processes, can be triggered by various factors that require to be meticulously determined and dealt with to make sure the integrity of the weld joint. Additionally, running a finger or a finger nail along the weld joint can often reveal undercut, as the surface may really feel unequal or have a dip where the undercut exists.

Using appropriate welding techniques and keeping control over vital welding specifications are crucial strategies for welders intending to avoid undercut in their weld joints.In conclusion, recognizing, preventing, and fixing undercut welding problems in your welding jobs is essential for guaranteeing durable and solid welds. By comprehending the typical reasons of undercut, being able to determine it in welds, carrying out preventive actions, and making use of correct strategies for taking care of undercut, you can stay clear of potential concerns and develop premium welds.

Report this page